A Guide to Avoiding Pitfalls in Quantum Board Installation: 5 Common Mistakes That Halve the Life of a Fixture!

April 8, 2025

By lightmyleaf

April 8, 2025

By lightmyleaf

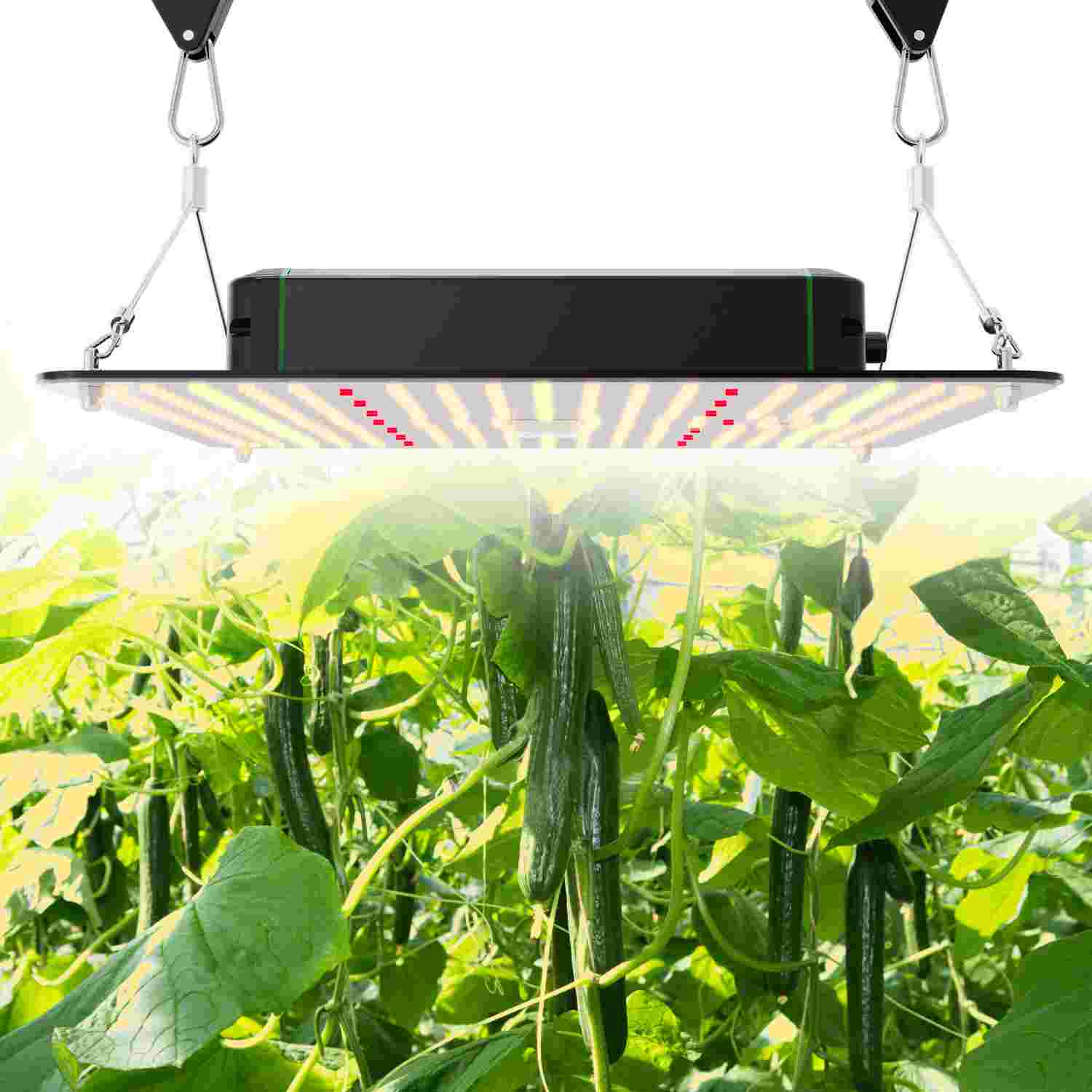

Don't ruin the potential of Quantum Panels by installing them!

Quantum Panel LEDs are the preferred choice of indoor growers due to their high performance, full spectrum coverage, and ultra-long lifespan. However, according to our research, 70% of fixture failures stem from improper installation rather than defects in the product itself. In this article, we will reveal the 5 fatal errors, to help you avoid the “life killer”, so that every penny is worth spending!

Problem: Although the quantum board passive cooling design, but if the confined space “trapped”, the temperature rises 10 ° C each, the speed of light decay accelerated by 20%, the life of a direct cut in half!

Keep ventilated: keep at least 15cm gap around the lamps and avoid direct contact with the insulation film at the top.

Add a fan: In a confined space (such as a tent), use a low-noise circulating fan to assist in heat dissipation.

Monitor the temperature: Check regularly with an infrared thermometer to ensure that the surface of the lamp body does not exceed 50°C.

Keywords: quantum board thermal design, LED grow light temperature control, passive thermal optimization

Problem: Too high = light efficiency is compromised, too low = plants are burned. Wrong height can lead to 30% of light energy waste!

General formula: Height (cm) = Lamp PPF ÷ 100 × 1.2 (applicable from seedling to flowering).

Adjust in stages:

Seedling stage: 40-60cm (to promote stem elongation)

Flowering stage: 25-40cm (enhance flower density)

Tool aid: use a PAR light intensity meter to measure leaf spot uniformity.

Keywords: quantum plate installation height, plant grow light PPF optimization, PAR light intensity test

Problem: Grid fluctuations or poor-quality power supplies can cause damage to the driver module, with repair costs as high as 40% of the fixture price!

Voltage stabilizer must: especially for rural or old grid environments.

Choose a wide voltage power supply: a high-quality quantum board supports AC100-277V input, automatically adapted to the voltage.

Lightning protection measures: thunderstorm areas with surge protectors to avoid lightning damage to the circuit.

Keywords: LED planting voltage requirements, voltage regulator selection, power surge protection

Problem: High humidity environment (such as hydroponic room) using IP40 lamps? Just wait for the lamp beads to rust and the driver to short-circuit!

Choose the rating according to the scenario:

General greenhouse: IP54 (splash proof)

Hydroponic/mist culture area: IP67 (submersible)

Regular inspection: Wipe the lamp body with a damp cloth every quarter and observe whether the sealing tape is aging.

Keywords: LED waterproof rating, hydroponics grow light requirements, IP67 lamps and lanterns advantages

Problem: Inferior cable resistance is too large, long time high load operation may cause short circuits or even fire!

Cable matching power: per meter of cable capacity ≥ lamp power × 1.5 (safety factor).

Avoid winding: excessive bending of the cable will lead to internal copper wire breakage, increasing resistance.

Specialized connectors: use waterproof male and female plugs to eliminate bare wires.

Keywords: LED grow light cable selection, electrical safety codes, fire cable standards

Installation is not “plug in and done”, but a battle of science + details. Check your fixtures now:

✅ Is there enough space for heat dissipation?

✅ Is the installation height reasonable?

✅ Is the power supply stable and reliable?

Lightmyleaf Professional Tip: Regular maintenance (quarterly cleaning + checking) can extend the life of your fixtures by 2-3 years, saving you enough money to upgrade to new equipment!

Tags